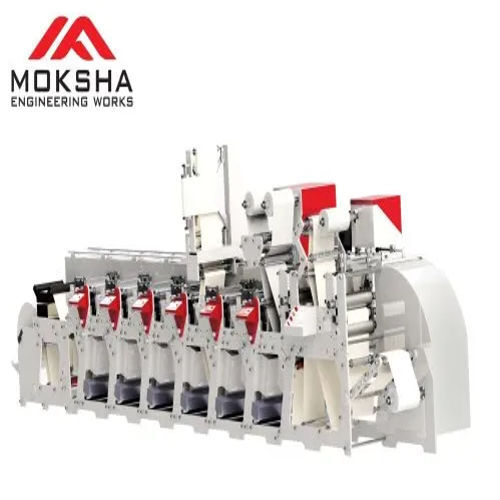

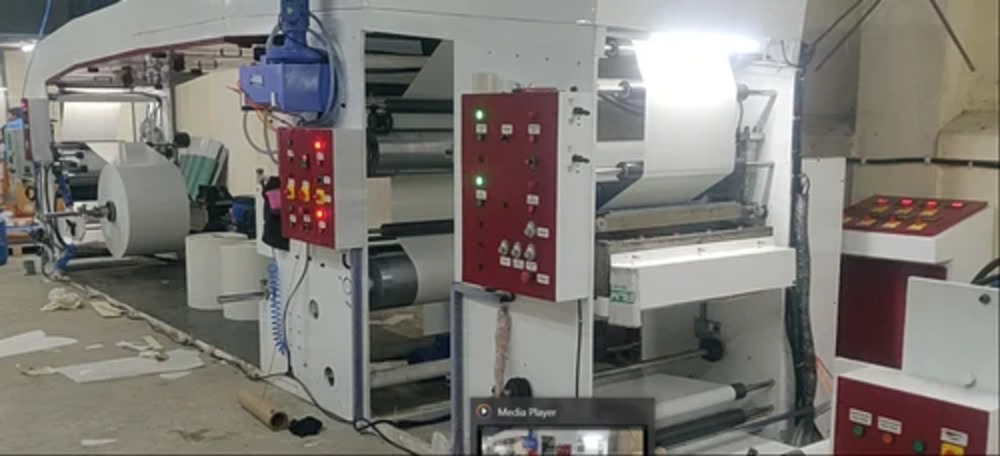

High Quality Flexo Printing Machine

Price 6000000 INR/ Unit

High Quality Flexo Printing Machine Specification

- Type

- High Quality Flexo Printing Machine

- Material

- IRON

- Capacity

- 6000-12000 pieces/hour

- Printing Speed

- 60-120 m/min

- Computerized

- Yes, Yes

- Automatic Grade

- Semi-Automatic

- Plate Type

- Flexible Photopolymer Plate, Photopolymer Plate

- Print Direction

- Both Sides (Duplex), Both Side Printing

- Ink Type

- Water-Based / Solvent-Based Ink, Water Based / Solvent Based

- Color Management

- Multicolor (2/4/6/8 Colors), Multi-color (up to 8 colors)

- Control System

- PLC Touch Screen Control, PLC Control with Touch Screen Interface

- Working Temperature

- 5C - 40C

- Power

- 12-18 kW

- Size

- Standard/Customisable

- Width

- 800-1500 mm

- Weight (kg)

- 2400-4200 kg

- Dimension (L*W*H)

- 3200mm x 1800mm x 2100mm

- Drying Method

- Hot Air and IR Dryer

- Application

- Label, Packaging, Bags, Wrappers, Tapes, and More

- Operator Requirement

- 1-2 persons

- Safety Features

- Emergency Stop, Safety Covers, Interlock System

- Noise Level

- <75 dB

- Max Plate Thickness

- 2.84 mm

- Unwind/Rewind Diameter

- 800 mm Maximum

- Tension Control

- Automatic Tension Control System

- Printing Material

- Paper, Film, Laminates, Non-woven Fabric

- Roller Type

- Anilox Ceramic Roller

- Power Supply

- 380V, 3 Phase, 50/60Hz

- Registration Accuracy

- ±0.15 mm

High Quality Flexo Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- ALL india and export

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About High Quality Flexo Printing Machine

Feature-Rich Flexo Press for Vast Applications

Our High Quality Flexo Printing Machine boasts automated tension control, anilox ceramic rollers, hot air and IR drying, and duplex capability-guaranteeing precision and versatility. Applications span labels, packaging, wrappers, tapes, and beyond. With multi-color support (up to 8 colors), water-based or solvent ink options, and a computerized PLC interface, you can effortlessly switch between substrates such as paper, film, laminates, and non-woven fabric. Deliver flawless prints with efficient, streamlined operation.

Swift Delivery & Competitive Proposals

Expect prompt delivery and transparent pricing with each order. List price and proposal amount are tailored for your requirements, with express shipping available to major export markets including Asia, Africa, and the Middle East. Standard delivery times typically range from 25-40 days. Samples are available for qualified buyers, enabling you to witness first-hand the grand capability and quality our monumental flexo machine brings to your production line.

FAQ's of High Quality Flexo Printing Machine:

Q: How does the automatic tension control system work in this flexo printing machine?

A: The automatic tension control system ensures consistent web tension throughout the printing process, minimizing material waste and enhancing registration accuracy. It actively adjusts depending on the printing material, contributing to smooth and precise operation.Q: What types of printing applications can this machine handle?

A: This high quality flexo printing press is versatile, suitable for producing labels, packaging, bags, wrappers, tapes, and similar items using paper, film, laminates, and non-woven fabric materials.Q: When can I expect delivery after placing an order?

A: Delivery usually takes between 25 to 40 days depending on your customization requirements and location, with express shipping options available for urgent orders.Q: Where can the flexo printing machine be exported?

A: We export worldwide, with main export markets in Asia, Africa, and the Middle East. Please contact us for shipping details to your specific country.Q: What is the process for obtaining a sample machine or print sample?

A: Qualified buyers may request a sample or printed sample. Please reach out with your requirements, and we will provide details regarding sample availability, lead time, and costs.Q: How does duplex (both side) printing enhance my production?

A: Duplex printing allows simultaneous printing on both sides of the material, increasing production speed and enabling broader design options for packaging and labels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Type Flexo Printing Machine Category

Modular Type Flexo Printing Machine

Price 10000000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 8000 Kg Kilograms (kg)

Material : Supported Material, Paper, Sticker Paper

Automatic Grade : Automatic

Printing Speed : 100 m/m

Color Label Printing Machine

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 800 kg

Material : Stainless Steel and Mild Steel

Automatic Grade : SemiAutomatic

Printing Speed : 070 m/min

Automatic Horizontal Flexographic Printing Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 2000 kg

Material : IRON

Automatic Grade : Automatic

Printing Speed : 40 m/m

Automatic Flexographic Printing Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx 1200 kg

Material : IRON

Automatic Grade : Automatic

Printing Speed : 40 m/m

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese