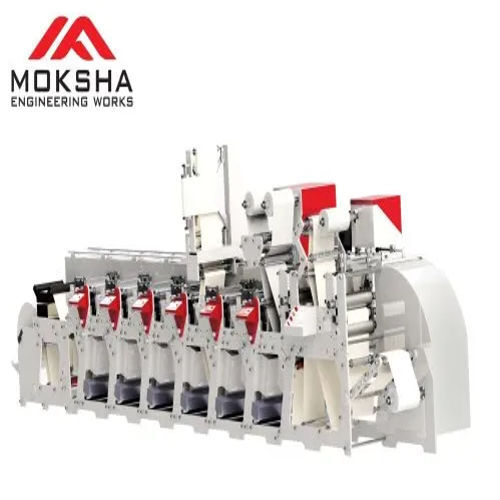

Automatic Horizontal Flexographic Printing Machine

Price 2500000 INR/ Unit

Automatic Horizontal Flexographic Printing Machine Specification

- Type

- Automatic Horizontal Flexographic Printing Machine

- Material

- IRON

- Capacity

- Customizable

- Printing Speed

- 40 m/m

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Photopolymer Plate

- Print Direction

- Horizontal

- Ink Type

- Water-based Ink

- Color Management

- Single Color

- Control System

- PLC Control

- Working Temperature

- 5C-40C

- Power

- 5 kW

- Size

- Medium to Large

- Width

- 600-1200 mm

- Weight (kg)

- 2000 kg

- Dimension (L*W*H)

- 3000*1500*1800 mm

- Unwind/Rewind

- Air Shaft

- Frame Structure

- Heavy Duty

- Max Roll Diameter

- 800 mm

- Tension Control

- Automatic

- Drying System

- Hot Air

- Substrate Support

- Paper, Thin Film

- Noise Level

- Low

- Register Accuracy

- ±0.15mm

- Operation Panel

- Touchscreen

- Feeding Type

- Web-fed

Automatic Horizontal Flexographic Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- ALL india and export

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Automatic Horizontal Flexographic Printing Machine

Primary Competitive Advantages & Application Spectrum

This automatic flexographic printing machine stands out for its heavy-duty iron frame and sophisticated PLC control system. The pristine web-fed operation, powerful tension control, and low-noise performance make it ideal for fast-paced production lines. Suitable for commercial packaging, labeling, and industrial-grade printing, its customizable capacity and register accuracy give it an edge in multi-sector printing needs.

Sample Availability, Export Markets & Packaging Details

Samples of the Automatic Horizontal Flexographic Printing Machine can be promptly handed over for review before procurement. We cater to both domestic and international markets, ensuring timely arrival for our global clientele. Packaging is conducted in robust, pristine material to protect each component during shipment. Our expertise ensures minimal transit damage, making us a trusted supplier throughout India and beyond.

FAQ's of Automatic Horizontal Flexographic Printing Machine:

Q: How does the automatic tension control benefit printing operations?

A: Automatic tension control optimizes substrate handling, reducing misalignment and print errors, thereby ensuring pristine and consistent results even at high speeds.Q: What are the main applications of this flexographic printing machine?

A: This machine is ideal for printing on paper and thin film-widely used for packaging, labeling, and commercial printing in various industries seeking polished output.Q: Where can samples of the machine be procured for evaluation?

A: Samples can be handed over directly by our supplier to interested buyers in domestic or international markets, enabling thorough assessment of the machine's capabilities.Q: What is the process for setting up the web-fed feeding system?

A: The machine features a computerized panel that guides the operator through web-fed setup, ensuring efficient feeding and reducing manual errors during operation.Q: When is the optimal working temperature range for this machine?

A: Optimal performance is achieved within a working temperature range of 5C to 40C, safeguarding register accuracy and print quality over prolonged operation.Q: What makes the drying system effective for thin film substrates?

A: The built-in hot air drying system delivers even heat distribution, facilitating quick and uniform ink curing, especially critical for thin film and paper substrates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Type Flexo Printing Machine Category

Modular Type Flexo Printing Machine

Price 10000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Supported Material, Paper, Sticker Paper

Ink Type : Other, Waterbased Ink, Solventbased Ink

Plate Type : Other, Photopolymer Plate

Size : Standard

Servo Base Fully Automatic Flexo Printing Machine

Price 18000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : IRON

Ink Type : Other, Waterbased / Solventbased

Plate Type : Other, Photopolymer Plate

Size : Standard / Customizable

Colour Automatic Flexographic Printing Machine

Price 20000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : IRON

Ink Type : Other, Waterbased Ink

Plate Type : Other, Photopolymer Plate

Size : Medium Industrial

4 Colour Printing With Die Cutting And Stamping Machine

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : IRON

Ink Type : Other, Waterbased / Oilbased

Plate Type : Other, Flatbed / Rotary

Size : Largeformat

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese